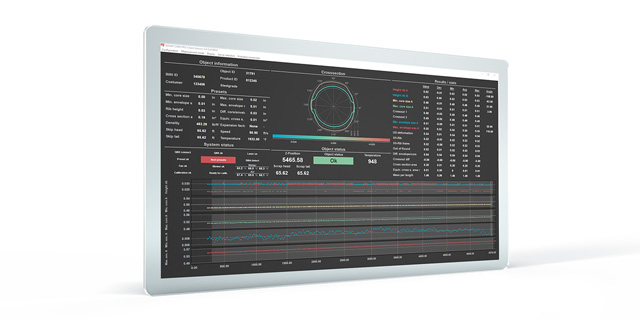

SMART CORE PRO software provides users of CONTOUR CHECK SHAPE systems with intelligently configured geometrical data that can be applied directly in the process line, as well as in the data structures of an Industry 4.0 production environment.

Key figures

1

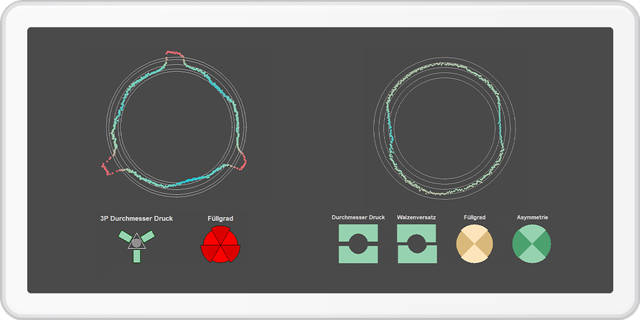

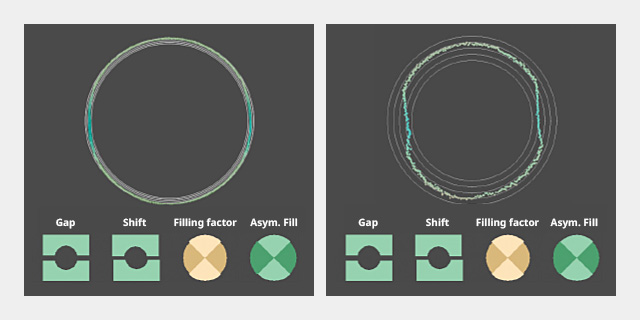

Profile shapes evaluable

1

Measurement frames in parallel

1

Display elements

<0

Evaluation parameters