Powerful laser projections for robust precast concrete parts

Enhanced visibility, improved process reliability, and time savings of up to 70%: the CAD-PRO Xpert sets new standards for laser projection in precast concrete parts production.

With the CAD-PRO Xpert laser projection system, LAP is setting new benchmarks in precast concrete production. This laser system offers higher precision, improved visibility, and increased process reliability—even in challenging production environments. Max Mandt-Merck, an industry expert at LAP, explains how precast concrete plants can benefit from these features in multiple ways.

High ceilings, bright light—precise projections

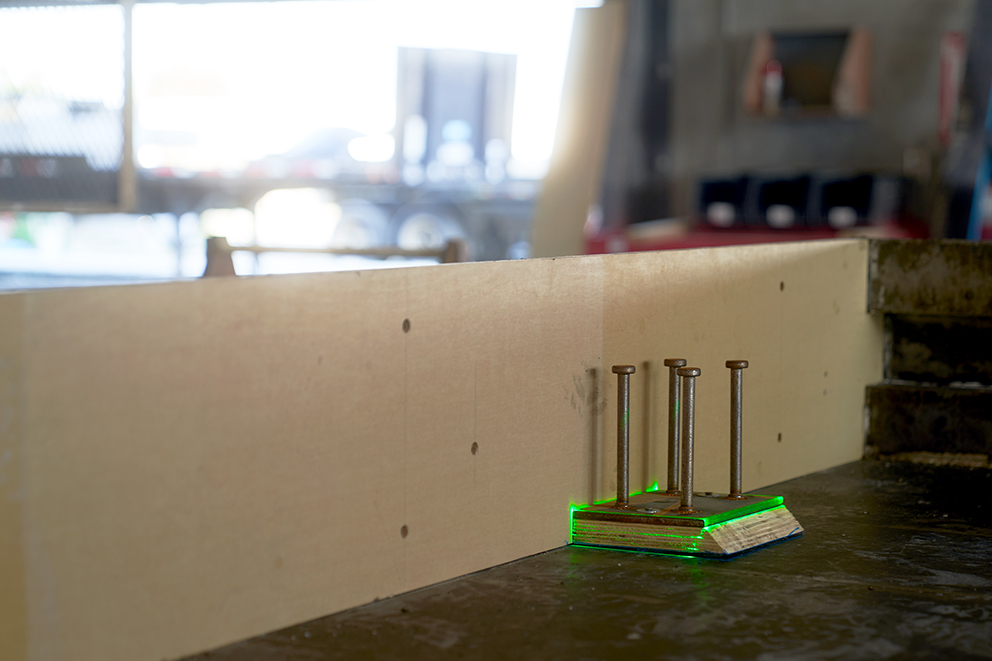

In precast concrete production, ceiling heights of eight to over ten meters and brightly lit areas, often flooded with daylight from doors and windows, are common. These conditions present challenges for laser projection systems, but they can be effectively addressed. "In demanding production environments, a laser projector must deliver significantly higher performance," says Max Mandt-Merck, Sales Manager at LAP. "This is precisely where the powerful technology platform of CAD-PRO Xpert excels."

Visibility at ten meters and beyond

The visibility of laser lines has been significantly enhanced with the CAD-PRO Xpert laser projection system. Even at projection distances of ten meters and more, the projector delivers stable, smooth, and highly visible projections with a precision of up to 0.05 mm per meter. The projected geometries on pallets and tables remain clearly visible, even in strong ambient light.

Boost function and redundancy: reliability during operation

If you need more brightness, you can increase it using the "boost function”. For this purpose, CAD-PRO Xpert can be optionally equipped with a second laser source. "Alternatively, the second laser source can serve as a fail-safe protection," explains Mandt-Merck. "This redundancy function offers multiple benefits: it reduces downtime and repair costs, extends the device's lifespan, and ensures process reliability. It's truly a game changer for many of our customers."

Field experience shows clear advantages: Up to 70% time savings

With over 20 years of industry experience, the LAP expert states, "As cost pressures rise and quality requirements become more stringent, laser projection systems have become essential tools for optimizing processes and ensuring quality in the concrete industry." At the same time, there is a growing demand for higher-performance solutions." Even now, LAP's laser projection systems help reduce errors, enhance process efficiency, and reliably support compliance with tolerances. "The results are impressive: some of our customers report time savings of up to 70% while consistently maintaining high quality."

Mandt-Merck emphasizes, "With this new system, we are once again setting new standards—in speed, precision, projection quality, and ergonomics—providing a solution that is ideally tailored to the needs of modern, forward-thinking plants."