The Application

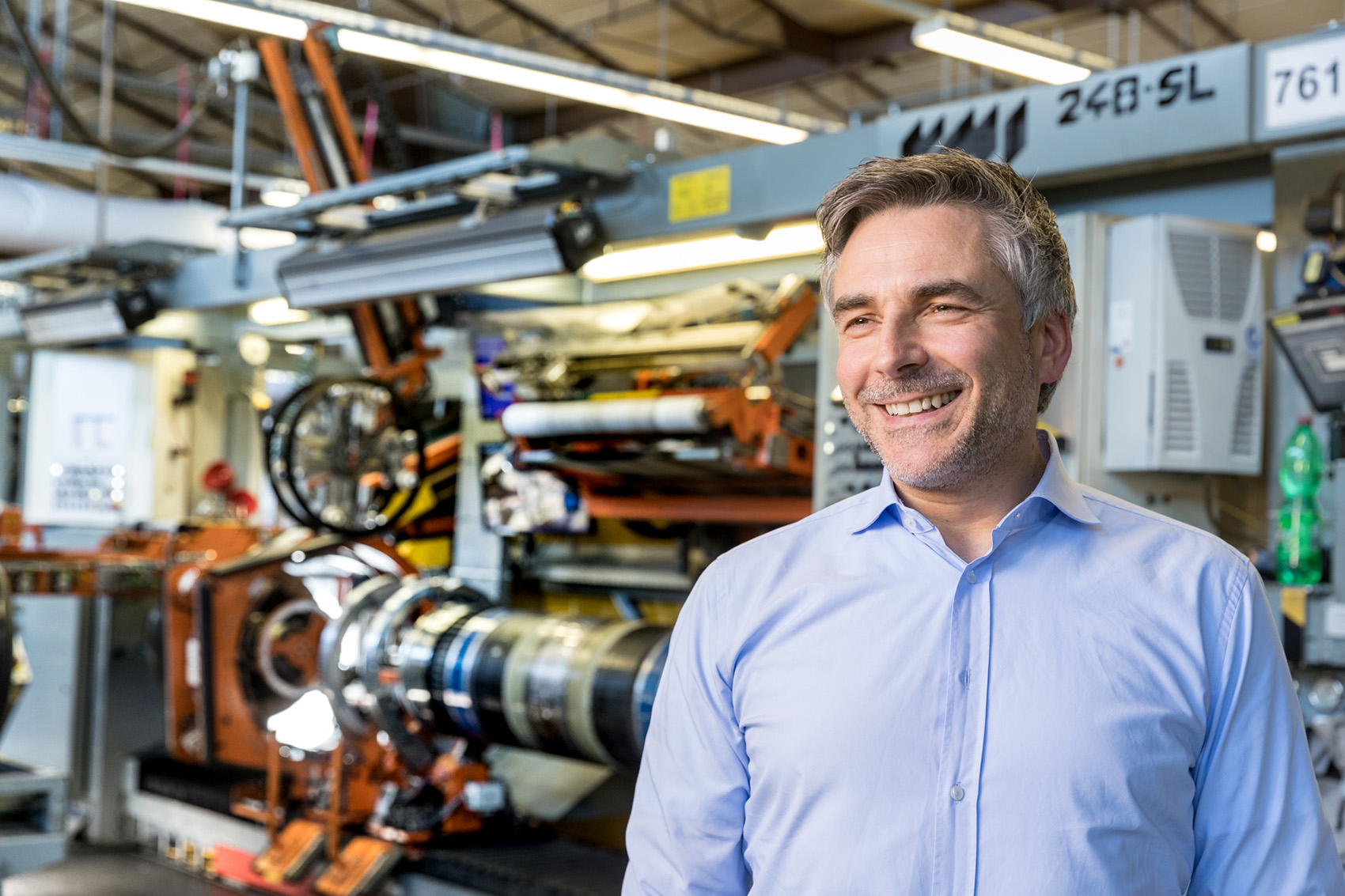

The demands on the quality of Pirelli’s products are correspondingly high, as well as on the performance of its machines and machine components. At the same time, the production of small batches requires extraordinary flexibility. “In our tire-building machines, the original first- and second-generation of LAP’s SERVOLASERs are giving dependable service for quality assurance,” says Sven Beck, Director of Change Management at Pirelli Deutschland. The positioning lasers have been successfully helping Pirelli maintain its high product quality for 20 years.

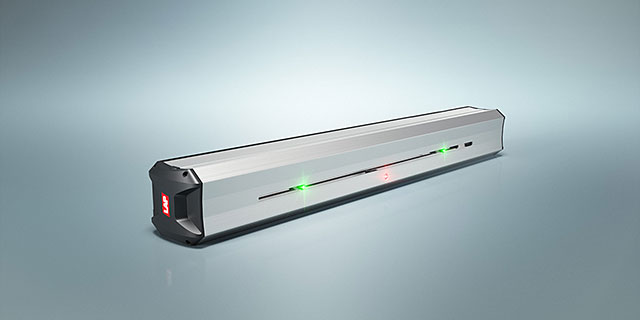

When the time came for a machine upgrade, Pirelli decided to integrate the third generation, the SERVOLASER Xpert, in the Breuberg facility. The movable positioning systems ensure the precise positioning of the tire layers during tire building. Two laser lines are projected in parallel, marking the target position of the individual layers on the tire-building drum. The operator can ensure that the layers are applied in the exact positions, and correct them if necessary.

Pirelli can also quickly respond to the market needs. In that regard, Sven Beck notes: “To provide the version variety demanded by the market, we have to be flexible and reconfigure our machines frequently. Here again, the SERVOLASER is a great help.”

Download the full application report below. Watch the appliaction video and get more information here.